Posted on: Post Date – 12:20 AM, Thurs – 11/17/22

Hyderabad: Since the development of 3D printing technology, there has been a lot of real hype and hope surrounding its potential use in printing internal organs of the human body. What if 3D printing could print an organ from a patient’s own cells? In this way, there is no risk of the patient’s immune rejection of the organ, solving the chronic shortage of human organs once and for all.

Driven by this commitment, the use of 3D printing to “fabricate” human organs has become a major field of study for researchers worldwide over the past few years. So far, researchers have had success with 3D printed implants for dentistry, prosthetics, and synthetic material organ models. However, none of them have managed to print a functional human organ that could be easily transplanted into a patient without the risk of physical rejection.

Currently, scientists have moved from printing with plastic and metal to using human cells to build tissues. While 3D-printed tissues for ears, skin and even blood vessels are in clinical trials, the technology is at least a decade away from a situation where patients can order organs from a 3D-printed kiosk and have them transplanted without any major complications.

3D printing of the cornea by LV Prasad

While many of the world’s top research institutions are conducting cutting-edge research on 3D printing of human tissue, in their hometown of Hyderabad, scientists from institutions as diverse as LV Prasad Eye Institute (LVPEI), CCMB, and IIT-Hyderabad have adopted the The first important step in the eye’s development of a 3D cornea. Researchers from the three institutions have successfully 3D printed and transplanted artificial corneas into rabbit eyes for the first time in India.they developed a

3D printed corneas from human donor corneal tissue. Developed locally with government and philanthropic funding, the product is completely natural, free of synthetic ingredients, animal residue and safe to use. Using decellularized corneal tissue matrix and human eye-derived stem cells, researchers developed a unique biomimetic hydrogel (patent pending) for use as a background material for 3D printed corneas.

While corneal substitutes are being actively researched around the world, these are either animal-based or synthetic. Pig or other animal products are not suitable for major parts of India and developing countries due to issues related to social and religious acceptability. In contrast, the researchers say these tissue-based 3D printed corneas are not only safer but also more affordable for corneal blindness patients in India.

So how does bioprinting work?

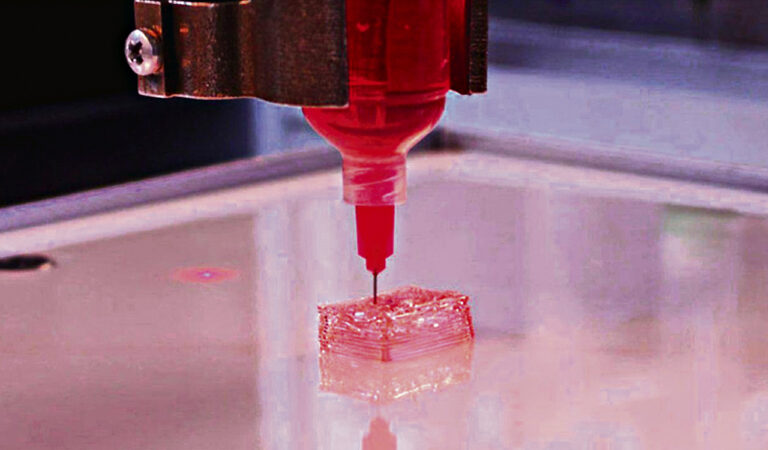

While traditional 3D printers build objects layer by layer, 3D bioprinters use human cells and other biological materials to create tissue-like structures with living cells. Some other definitions of 3D bioprinting include the ability to assemble multiple cell types, growth factors, and biomaterials in a layer-by-layer fashion to produce bioartificial organs that can mimic natural organs.

The Wyss Institute at Harvard University has done pioneering work in developing human tissue through 3D bioprinting. Jennifer Lewis, lead researcher and professor at the Wyss Institute at Harvard University, said on the Wyss website: “Multidisciplinary research at the Wyss Institute has led to the development of a multi-material 3D bioprinting method that produces Vascularized tissues that were almost ten times thicker than previously engineered tissues and maintained their structure and function for up to six weeks.”

Despite a lot of innovative research being done, difficulties persist. A major challenge is that scientists haven’t quite figured out a way to build vasculature through 3D bioprinting. Vasculature is important because any human organ or tissue, even one developed through 3D bioprinting, requires constant blood flow to survive. To this end, the complex vascular networks within human organs must also be developed through 3D bioprinting, which remains a challenge.